CRYOCOOLER APPLICATIONS

[sws_button class=”” size=”sws_btn_small” align=”sws_btn_align_left” href=”http://tristantech.com/wp-content/uploads/2013/10/Cryocooler-Apps.pdf” target=”_blank” label=”Download the PDF” template=”sws_btn_midnightblue” textcolor=”000000″ fontweight=”normal” bgcolor=”” bgcolorhover=”” glow=”sws_btn_glow” btnwidth=”” textalign=”center”] [/sws_button]

[sws_divider_small_padding]

The disadvantage of liquid cryogens is that they must be replenished, sometimes on a daily basis. Mechanical refrigerators eliminate that chore, but add cost, vibration and, in the case of SQUID-based instrumentation, magnetic noise. Cryocoolers can be used to reduce boiloff by cooling radiation shields.

As early as 1980, a 200 liter cryocooled dewar was used by GWR Instruments (San Diego, CA) for a superconducting gravimeter. This system used a removable three stage CTI cryocooler. With the cryocooler operating, the boiloff was less than 0.2 liters/day (providing 1000+ day hold time).

The key to vibration-free systems is to acoustically decouple the cryocooler from the dewar. One method of decoupling is a thick rubber gasket at the physical interface between the dewar and the mechanical cooler and flexible copper braids for thermal contact rather than a rigid mounting point(s). In the GWR system, magnetic noise was not a significant factor.

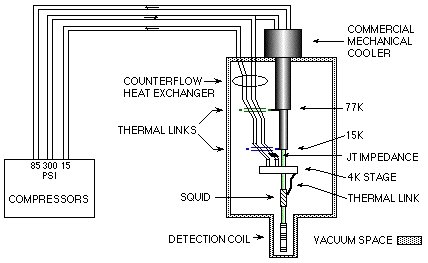

CryoSQUID was a hybrid system1 that eliminated the need for liquid cryogens. It incorporated a Gifford–McMahon (GM) cycle and a Joule-Thompson (JT) refrigerator designed to provide cooling of a commercial dc SQUID (see figure below) to 4 K.

The system was designed around an off-the-shelf, two stage GM cooler having one watt cooling power at 15 K. A helium gas JT stage was added and ran at an input pressure of 2 MPa with a return pressure of 100 kPa. The GM section used the same input pressure and a return pressure of 570 kPa with two standard helium compressors providing the gas supplies. The cool-down time from 300 K was approximately 24 hours. The use of a JT cycle for the low temperature stage significantly reduced the temperature fluctuations of a pure mechanical cryocooler. A suspension system at the JT stage was designed to minimize the vibration transmitted to the SQUID and detection coil from the GM stage. This system has operated successfully at equivalent noise levels of 2 x 10-14 Tesla/√Hz.

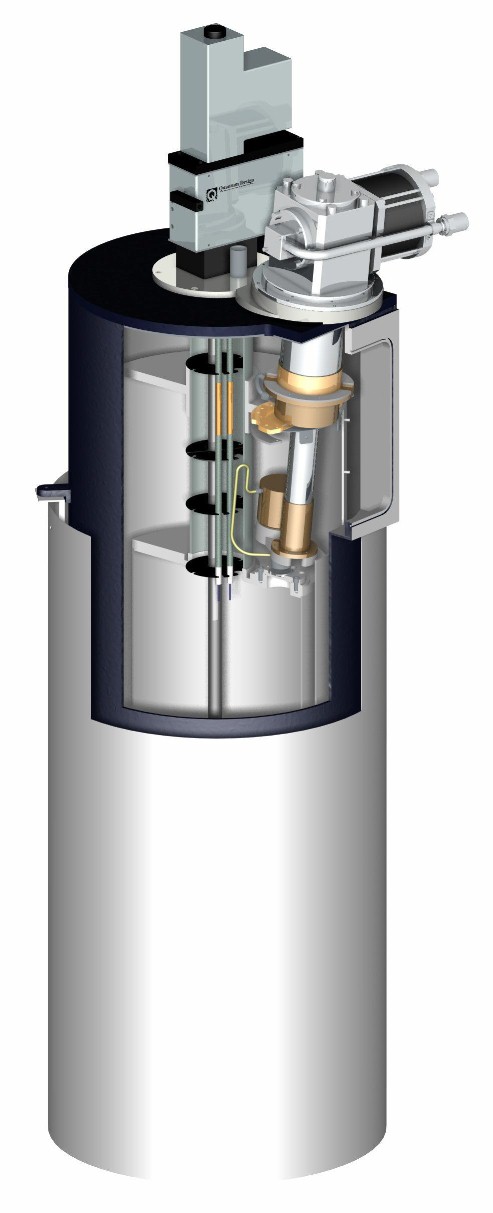

The Quantum Design EverCool is another example of closed cycle refrigeration where low vibration is critical. This system is used to condense liquid helium in a variable temperature SQUID susceptometer. While the ability to operate without the need for liquid cryogen refills has many advantages, the vibration induced by the two stage refrigerator is detectable.

Cryocoolers can be classified by performance. For example:

- Miniature (low capacity for electronic and instrumentation applications)

- Small (general purpose laboratory and commercial systems)

- Intermediate (small-scale gas liquefaction and industrial superconducting systems)

- Large (large scale gas liquefaction systems, LNG production, tonnage oxygen, helium recovery, etc.)

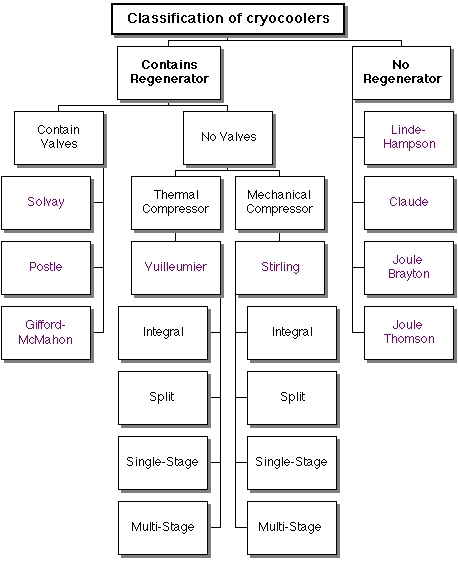

Cryocoolers can also be classified by the type of cycle used and the construction (see figure, types designated in purple).

The compressor can be mechanical or acoustical. Pulse tube refrigerators offer the possibility of nearly vibration free operation. This may have significant advantages when used to cool SQUID magnetometers such as shown in the figure below.

Different refrigeration cycles can be compared using the following parameters:

Coefficient of Performance (COP) = (Refrigeration Capacity) / (Power Input)

= (Heat Removed) / (Work Done)

The Ideal (Carnot) Coefficient of Performance is given by:

COP = TC / (TH – TC) where TC is the minimum temperature and TH is the maximum temperature in the refrigeration cycle.

And, the efficiency, η, is given by:

η = (Actual COP) / (Carnot COP) where, typically, η < 0.5 or 50%.

When considering the use of a closed cycle refrigeration system, both thermodynamic and operational parameters must be taken into consideration. The first consideration is usually the required operating temperature, followed by the available refrigeration capacity.

System performance is also determined by the total mass to be cooled, the thermal conductance between the refrigerator and the item to be cooled, and the cool down time. For systems that are used to cool SQUID sensors, mechanical vibration, electromagnetic emission and magnetic signature must all be taken into account. For Split systems (see Figure 2), one must be concerned about flexible vs. inflexible leads and the thermal influence of warm and cold leads on the cryogenic region.

Other considerations include the following: reliability and operating life (mean time before failure and mean time before maintenance); shelf life; cost; whether or not an external (water or air) cooling system is needed for the compressor; tolerance to vibration and acceleration; orientation problems (must the cryocooler be in a specific orientation); and, for aerospace applications, low/zero gravity environmental concerns.

REFERENCES

1) D. S. Buchanan, D. N. Paulson and S. J. Williamson, in: Advances in Cryogenic Engineering, vol. 33, R. W. Fast, ed., Plenum, New York, 1988, p. 97

2) K. Sata, S. Fujimoto, N. Fukui, E. Haraguichi, T. Kido, N. Nishiguachi and Y.M. Kang, Development of a 61-Channel MEG System Cooled by a GM / JT Cryocooler. In: C.J. Aine, Y. Okada, G. Stroink, S.J. Swithenby, C.C. Wood, Biomag 96 Proceedings of the Tenth International Conference on Biomagnetism , Springer, New York, 2000, Vol. 1, pp. 114-117.

OTHER REFERENCES

“Cryocoolers Part 1: Fundamentals”, Graham Walker, Plenum Press, New York, 1983.

“Cryocoolers Part 2: Applications”, Graham Walker, Plenum Press, New York, 1983.